- Pressure Vessel Nameplate Data Sheet

- Pressure Vessel Nameplate Data Logger

- Pressure Vessel Nameplate Data Chart

- Pressure Vessel Nameplate Requirements

- Pressure Vessel Nameplate Data Types

- Pressure Vessel Nameplate Stampings

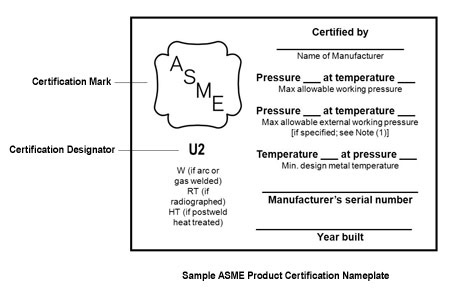

The Pressure Vessel Plate article provides you information about the ASME Code requirement regarding plate material and related points in the pressure vessel inspection. You need to take care about your. Pressure Vessel Failed Inspection Internal Inspection. Although it is an extremely rare occurrence, pressure vessels sometimes fail to pass muster. In this case, we will inform the owner of the pressure vessel or the responsible manager together with recommendations that can be used to rectify the problem (where applicable). These vessels also require an authorized inspector to sign off on every new vessel constructed and each vessel has a nameplate with pertinent information about the vessel, such as maximum allowable working pressure, maximum temperature, minimum design metal temperature, what company manufactured it, the date, its registration number (through.

Pressure vessel with uniform internal pressure is considered. The properties used are as follow: E = 5 × l0 6 psi, Poisson's ratio v = 0.16, and uniform pressure p = 100 psi. The gradually refined meshes using. Pressure vessels in most services. ASME’s Boiler and Pressure Vessel Committee adopted substantially identical provisions and published them as a nonmandatory appendix in the 1950, 1952, 1956, and 1959 editions of Section VIII of the ASME Boiler and Pressure Vessel Code.

The ASME Boiler & Pressure Vessel Code (BPVC) is an American Society of Mechanical Engineers (ASME) standard that regulates the design and construction of boilers and pressure vessels.[1] The document is written and maintained by volunteers chosen for their technical expertise .[2] The ASME works as an accreditation body and entitles independent third parties (such as verification, testing and certification agencies) to inspect and ensure compliance to the BPVC.[3]

History[edit]

The BPVC was created in response to public outcry after several serious explosions in the state of Massachusetts. A fire-tube boiler exploded at the Grover Shoe Factory in Brockton, Massachusetts, on March 20, 1905, which resulted in the deaths of 58 people and injured 150. Then on December 6, 1906, a boiler in the factory of the P.J. Harney Shoe Company exploded in Lynn, Massachusetts. As a result, the state of Massachusetts enacted the first legal code based on ASME's rules for the construction of steam boilers in 1907.[4][5]

ASME convened the Board of Boiler Rules before it became the ASME Boiler Code Committee which was formed in 1911. This committee put in the form work for the first edition of the ASME Boiler Code - Rules for the Construction of Stationary Boilers and for the Allowable Working Pressures, which was issued in 1914 and published in 1915.[5]

The first edition of the Boiler and Pressure Vessel Code, known as the 1914 edition, was a single 114-page volume.[6][7] It developed over time into the ASME Boiler and Pressure Vessel code, which today has over 92,000 copies in use, in over 100 countries around the world.[5] As of March 2011 the document consisted of 16,000 pages in 28 volumes.[7]

After the first edition of the Code, the verifications required by the Code were performed by independent inspectors, which resulted in a wide range of interpretations. Hence in February 1919, the National Board of Boiler and Pressure Vessel Inspectors was formed.[5]

| Year | Activity |

|---|---|

| 1880 | The American Society of Mechanical Engineers is founded |

| 1884 | First performance test code: Code for the Conduct of Trials of Steam Boilers |

| 1900 | First revision of an ASME standard, Standard Method of Conducting Steam Boiler Tests |

| 1911 | Establishment of a committee to propose a Boiler Code |

| 1913 | New Committee to revise the Boiler Code |

| 1914 | Issuance of the first Boiler Code |

| 1915 | Standards for Specifications and Construction of Boilers and Other Containing Vessels in Which High Pressure is Contained |

| 1919 | National Board of Boiler and Pressure Vessel Inspectors formed |

| 1924 | Code for Unfired Pressure Vessels |

| 1930 | Test Code of Complete Steam-Electric Power Plants |

| 1956 | Committee established for ASME Pressure Vessel Code for Nuclear Age |

| 1963 | Section III (Nuclear Power) of ASME Boiler and Pressure Vessel Code |

| 1968 | ASME Nuclear Power Certificate of Authorization Program commences |

| 1972 | ASME expands its certification program worldwide; first ASME manufacturer certification issued outside of North America |

| 1978 | First ASME publication of Boiler and Pressure Vessel Committee interpretations |

| 1983 | ASME Boiler and Pressure Vessel Code published in both conventional and metric units |

| 1989 | Boiler and Pressure Vessel Code published on CD-ROM |

| 1992 | First Authorized Inspection Agency accredited |

| 1996 | Risk technology introduced into the Boiler and Pressure Vessel Code |

| 1997 | High Pressure Vessel Code |

| 2000 | C&S Connect (on-line balloting and tracking system) launched for Boiler and_Pressure Vessel Committees |

| 2007 | ISO TC11 Standard 16528—Boilers and Pressure Vessels published, establishing performance requirements for the construction of boilers and pressure vessels and facilitating registration of BPV Codes to this standard |

| 2007 | High density polyethylene plastic pipe introduced into the Boiler and Pressure Vessel Code, Section III, Code Case N-755 |

| 2009 | ASME Boiler and Pressure Vessel Committee reorganized from one consensus body to ten consensus bodies |

| 2015 | High density polyethylene plastic pipe incorporated into Boiler and Pressure Vessel Code, Section III, Mandatory Appendix XXVI |

Code Sections[edit]

LIST OF SECTIONS[9]

The following is the structure of the 2019 Edition of the BPV Code:[10]

- ASME BPVC Section I - Rules for Construction of Power Boilers

- ASME BPVC Section II - Materials

- Part A - Ferrous Material Specifications

- Part B - Nonferrous Material Specifications

- Part C - Specifications for Welding Rods, Electrodes and Filler Metals

- Part D - Properties (Customary)

- Part D - Properties (Metric)

- ASME BPVC Section III - Rules for Construction of Nuclear Facility Components

- Subsection NCA - General Requirements for Division 1 and Division 2

- Appendices

- Division 1

- Subsection NB - Class 1 Components

- Subsection NC - Class 2 Components

- Subsection ND - Class 3 Components

- Subsection NE - Class MC Components

- Subsection NF - Supports

- Subsection NG - Core Support Structures

- Division 2 - Code for Concrete Containments

- Division 3 - Containment Systems for Transportation and Storage of Spent Nuclear Fuel and High-Level Radioactive Material

- Division 5 - High Temperature Reactors

- ASME BPVC Section IV - Rules for Construction of Heating Boilers

- ASME BPVC Section V - Nondestructive Examination

- ASME BPVC Section VI - Recommended Rules for the Care and Operation of Heating Boilers

- ASME BPVC Section VII - Recommended Guidelines for the Care of Power Boilers

- ASME BPVC Section VIII - Rules for Construction of Pressure Vessels

- Division 1

- Division 2 - Alternative Rules

- Division 3 - Alternative Rules for Construction of High Pressure Vessels

- ASME BPVC Section IX - Welding, Brazing, and Fusing Qualifications

- ASME BPVC Section X - Fiber-Reinforced Plastic Pressure Vessels

- ASME BPVC Section XI - Rules for Inservice Inspection of Nuclear Power Plant Components

- Division 1 - Rules for Inspection and Testing of Components of Light-Water-Cooled Plants

- Division 2 - Requirements for Reliability and Integrity Management (RIM) Programs for Nuclear Power Plants

- ASME BPVC Section XII - Rules for the Construction and Continued Service of Transport Tanks

- ASME BPVC Code Cases - Boilers and Pressure Vessels

ADDENDA

Addenda, which include additions and revisions to the individual Sections of the Code, are issued accordingly for a particular edition of the code up until the next edition.[9] Addenda is no longer in use since Code Edition 2013. It has been replaced by two years edition period.

INTERPRETATIONS

ASME's interpretations to submitted technical queries relevant to a particular Section of the Code are issued accordingly. Interpretations are also available through the internet.[11]

CODES CASES

Pressure Vessel Nameplate Data Sheet

Code Cases provide rules that permit the use of materials and alternative methods of construction that are not covered by existing BPVC rules.[12] For those Cases that have been adopted will appear in the appropriate Code Cases book: 'Boilers and Pressure Vessels' and 'Nuclear Components.'[9]

Codes Cases are usually intended to be incorporated in the Code in a later edition. When it is used, the Code Case specifies mandatory requirements which must be met as it would be with the Code. There are some jurisdictions that do not automatically accept Code Cases.[9]

ASME BPVC Section II - Materials[edit]

The section of the ASME BPVC consists of 4 parts.

Part A - Ferrous Material Specifications

This Part is a supplementary book referenced by other sections of the Code. It provides material specifications for ferrous materials which are suitable for use in the construction of pressure vessels.[13]

The specifications contained in this Part specify the mechanical properties, heat treatment, heat and product chemical composition and analysis, test specimens, and methodologies of testing. The designation of the specifications start with 'SA' and a number which is taken from the ASTM 'A' specifications.[13]

Part B - Nonferrous Material Specifications

This Part is a supplementary book referenced by other sections of the Code. It provides material specifications for nonferrous materials which are suitable for use in the construction of pressure vessels.[13]

The specifications contained in this Part specify the mechanical properties, heat treatment, heat and product chemical composition and analysis, test specimens, and methodologies of testing. The designation of the specifications start with 'SB' and a number which is taken from the ASTM 'B' specifications.[13]

Part C - Specifications for Welding Rods, Electrodes, and Filler Metals

This Part is a supplementary book referenced by other sections of the Code. It provides mechanical properties, heat treatment, heat and product chemical composition and analysis, test specimens, and methodologies of testing for welding rods, filler metals and electrodes used in the construction of pressure vessels.[13]

The specifications contained in this Part are designated with 'SFA' and a number which is taken from the American Welding Society (AWS) specifications.[13]

Part D - Properties (Customary/Metric)

This Part is a supplementary book referenced by other sections of the Code. It provides tables for the design stress values, tensile and yield stress values as well as tables for material properties (Modulus of Elasticity, Coefficient of heat transfer et al.)[13]

ASME BPVC Section III - Rules for Construction of Nuclear Facility Components[edit]

Section III of the ASME Code Address the rules for construction of nuclear facility components and supports. The components and supports covered by section III are intended to be installed in a nuclear power system that serves the purpose of producing and controlling the output of thermal energy from nuclear fuel and those associated systems essential to safety of nuclear power system. Section III provides requirements for new construction of nuclear power system considering mechanical and thermal stresses due to cyclic operation. Deterioration, which may occur in service as result of radiation effects, corrosion, or instability of the material, is typically not addressed.

- Subsection NCA (General Requirements for Division 1 and Division 2)

- NCA-1000 Scope of Section III

- NCA-2000 Classification of Components and Supports

- NCA-3000 Responsibilities and Duties

- NCA-4000 Quality Assurance

- NCA-5000 Authorized Inspection

- NCA-8000 Certificates, Nameplates, Code Symbol Stamping, and Data Reports

- NCA-9000 Glossary

- Division 1- Metallic Components

- Subsection NB Class 1 components (Those components that are part of the fluid-retaining pressure boundary of the reactor coolant system. Failure of this pressure boundary would violate the integrity of the reactor coolant pressure boundary)

- Reactor Pressure Vessel

- Pressurizer Vessel

- Steam Generators

- Reactor Coolant Pumps

- Reactor Coolant Piping

- Line Valves

- Safety Valves

- Subsection NC Class 2 components (Those components that are not part of the reactor coolant pressure boundary, but are important for reactor shutdown, emergency core cooling, post-accident containment heat removal, or post-accident fission product removal)

- Emergency Core Cooling

- Post Accident Heat Removal

- Post Accident Fission Product Removal

- Includes Vessels, Pumps, Valves, Piping, Storage Tanks, and Supports

- Subsection ND Class 3 components (Those components that are not part of class 1 or 2 but are important to safety)

- Cooling Water Systems

- Auxiliary Feedwater Systems

- Includes Vessels, Pumps, Valves, Piping, Storage Tanks, and Supports

- Subsection NE Class MC supports

- Containment Vessel

- Penetration Assemblies (Does not include piping, pumps and valves which if passing through the containment must be class 1 or class 2)

- Subsection NF Supports

- Plate and Shell Type

- Linear Type

- Standar Supports

- Support Class is the class of the Component Supported

- Subsection NG Core Support Structures (class CS)

- Core Support Structures

- Reactor Vessel Internals

- Subsection NH Class 1 Components in Elevated Temperature Service (Those components that are used in elevated temperature service)

- Elevated Temperature Components

- Service Temperature over 800°F

- Appendices[14]

ASME BPVC Section V - Nondestructive Examination[edit]

The section of the ASME BPVC contains the requirements for nondestructive examinations which are referred and required by other sections of the Code.[15]

The section also covers the suppliers examination responsibilities, requirements of the authorized inspectors (AI) as well as the requirements for the qualification of personnel, inspection and examinations.[15][16]

ASME BPVC Section VIII - Rules for Construction of Pressure Vessels[edit]

The section of the ASME BPVC consists of 3 divisions.[17]

ASME Section VIII Division 1[edit]

division covers the mandatory requirements, specific prohibitions and nonmandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure which exceeds 15 psi (100 kPa).[9]

pressure vessel can be either fired or unfired.[17] The pressure may be from external sources, or by the application of heating from an indirect or direct source, or any combination thereof.[9]

The Division is not numbered in the traditional method (Part 1, Part 2 etc.) but is structured with Subsections and Parts which consist of letters followed by a number. The structure is as follows:[9]

- Subsection A - General Requirements

- Part UG - General Requirements for All Methods of Construction and All Materials

- Materials: UG-4 through to UG-15

- Design: UG-16 through to UG-35

- Openings and Reinforcements: UG-36 through to UG-46

- Braced and Stayed Surfaces: UG-47 through to UG-50

- Fabrication: UG-75 through to UG-85

- Inspection and Tests: UG-90 through to UG-103

- Marking and Reports: UG-115 through to UG-120

- Overpressure Protection: UG125 through to UG-140

- Subsection B - Requirements Pertaining to Methods of Fabrication of Pressure Vessels

- Part UW - Requirements for Pressure Vessels Fabricated by Welding

- General: UW-1 through to UW-3

- Materials: UW-5

- Design: UW-8 through to UW-21

- Fabrication: UW-26 through to UW-42

- Inspection and Tests: UW-46 through to UW-54

- Marking and Reports: UW-60

- Pressure Relief Devices: UW-65

- Part UF - Requirements for Pressure Vessels Fabricated by Forging

- General: UF-1

- Materials: UF-5 through to UF-7

- Design: UF-12 through to UF-25

- Fabrication: UF-26 through to UF-43

- Inspection and Tests: UF-45 through to UF-55

- Marking and Reports: UF-115

- Pressure Relief Devices: UF-125

- Part UB - Requirements for Pressure Vessels Fabricated by Brazing

- General: UB-1 through to UB-3

- Materials: UB-5 through to UB-7

- Design: UB-9 through to UB-22

- Fabrication: UB-30 through to UB-37

- Inspection and Tests: UB-40 through to UB-50

- Marking and Reports: UB-55

- Pressure Relief Devices: UB-60

- Subsection C - Requirements Pertaining to Classes of Materials

- Part UCS - Requirements for Pressure Vessels Constructed of Carbon and Low Alloy Steels

- General: UCS-1

- Materials: UCS-5 through to UCS-12

- Design: UCS-16 through to UCS-57

- Low Temperature Operation: UCS-65 through to UCS-68

- Inspection and Tests: UCS-90

- Marking and Reports: UCS-115

- Pressure Relief Devices: UCS-125

- Nonmandatory Appendix CS: UCS-150 through to UCS-160

Pressure Vessel Nameplate Data Logger

- Part UNF - Requirements for Pressure Vessels Constructed of Nonferrous Materials

- General: UNF-1 through to UNF-4

- Materials: UNF-5 through to UNF-15

- Design: UNF-16 through to UNF-65

- Fabrication: UNF-75 through to UNF-79

- Inspection and Tests: UNF-90 through to UNF-95

- Marking and Reports: UNF-115

- Pressure Relief Devices: UNF-125

- Appendix NF: Characteristics of the Nonferrous Materials (Informative and Nonmandatory)

- Part UHA Requirements for Pressure Vessels Constructed of High Alloy Steel

- General: UHA-1 through to UHA-8

- Materials: UHA-11 through to UHA-13

- Design: UHA-20 through to UHA-34

- Fabrication: UHA-40 through to UHA-44

- Inspection and Tests: UHA-50 through to UHA-52

- Marking and Reports: UHA-60

- Pressure Relief Devices: UHA-65

- Appendix HA: Suggestions on the Selection and Treatment of Austenitic Chromium–Nickel and Ferritic and Martensitic High Chromium Steels (Informative and Nonmandatory)

- Part UCI - Requirements for Pressure Vessels Constructed of Cast Iron

- General: UCI-1 through to UCI-3

- Materials: UCI-5 through to UCI-12

- Design: UCI-16 through to UCI-37

- Fabrication: UCI-75 through to UCI-78

- Inspection and Tests: UCI-90 through to UCI-101

- Marking and Reports: UCI-115

- Pressure Relief Devices: UCI-125

- Part UCL - Requirements for Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied Linings

- General: UCL-1 through to UCL-3

- Materials: UCL-10 through to UCL-12

- Design: UCL-20 through to UCL-27

- Fabrication: UCL-30 through to UCL-46

- Inspection and Tests: UCL-50 through to UCL-52

- Marking and Reports: UCL-55

- Pressure Relief Devices: UCL-60

- Part UCD - Requirements for Pressure Vessels Constructed of Cast Ductile Iron

- General: UCD-1 through to UCD-3

- Materials: UCD-5 through to UCD-12

- Design: UCD-16 through to UCD-37

- Fabrication: UCD-75 through to UCD-78

- Inspection and Tests: UCD-90 through to UCD-101

- Marking and Reports: UCD-115

- Pressure Relief Devices: UCD-125

- Part UHT Requirements for Pressure Vessels Constructed of Ferritic Steels With Tensile Properties Enhanced by Heat Treatment.

- General: UHT-1

- Materials: UHT-5 through to UHT-6

- Design: UHT-16 through to UHT-57

- Fabrication: UHT-75 through to UHT-86

- Inspection and Tests: UHT-90

- Marking and Reports: UHT-115

- Pressure Relief Devices: UHT-125

- Part ULW Requirements for Pressure Vessels Fabricated by Layered Construction

- Introduction: ULW-1 through to ULW-2

- Materials: ULW-5

- Design: ULW-16 through to ULW-26

- Welding: ULW-31 through to ULW-33

- Fabrication: ULW-75 through to ULW-78

- Inspection and Tests: ULW-90

- Marking and Reports: ULW-115

- Pressure Relief Devices: ULW-125

- Part ULT Alternative Rules for Pressure Vessels Constructed of Materials Having Higher Allowable Stresses at Low Temperature

- General: ULT-1 through to ULT-5

- Design: ULT-16 through to ULT-57

- Fabrication: ULT-76 through to ULT-86

- Inspection and Tests: ULT-90 through to ULT-100

- Marking and Reports: ULT-115

- Pressure Relief Devices: ULT-125

- Part UHX - Rules for Shell-and-Tube Heat Exchangers

- Part UIG - Requirements for Pressure Vessels Constructed of Impregnated Graphite

- General: UIG-1 through to UIG-3

- Materials: UIG-5 through to UIG-8

- Design: UIG-22 through to UIG-60

- Fabrication: UIG-75 through to UIG-84

- Inspection and Tests: UIG-90 through to UIG-112

- Marking and Reports: UIG-115 through to UIG-121

- MANDATORY APPENDICES: 1 through to 44

- NONMANDATORY APPENDICES: A through to NN

Division 2 - Alternative Rules[edit]

This division covers the mandatory requirements, specific prohibitions and nonmandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure which exceeds 3000 psi (20700 kPa) but less than 10,000 psi.[18]

The pressure vessel can be either fired or unfired.[17] The pressure may be from external sources, or by the application of heating from an indirect or direct source as a result of a process, or any combination of the two.[18]

The rules contained in this section can be used as an alternative to the minimum requirements specified in Division 1. Generally the Division 2 rules are more onerous than in Division 1 with respect to materials, design and nondestructive examinations but higher design stress intensity values are allowed.[17] Division 2 has also provisions for the use of finite element analysis to determine expected stress in pressure equipment, in addition to the traditional approach of design by formula (Part 5: 'Design by Analysis requirements').

Division 3 - Alternative Rules for Construction of High Pressure Vessels[edit]

This division covers the mandatory requirements, specific prohibitions and nonmandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure which exceeds 10,000 psi (70,000 kPa).[19]

The pressure vessel can be either fired or unfired.[17] The pressure may be from external sources, by the application of heating from an indirect or direct source, process reaction or any combination thereof.[19]

See also[edit]

References[edit]

- ^Antaki, George A. (2003). Piping and pipeline engineering: design, construction, maintenance, integrity, and repair. Marcel Dekker Inc. ISBN9780203911150.

- ^ASME Codes and StandardsArchived February 14, 2010, at the Wayback Machine

- ^Boiler and Pressure Vessel Inspection According to ASME

- ^Balmer, Robert T (2010). Modern Engineering Thermodynamics. 13.10 Modern Steam Power Plants: Academic Press. p. 864. ISBN978-0-12-374996-3.CS1 maint: location (link)

- ^ abcdeVarrasi, John (June 2009). 'To Protect and Serve - Celebrating 125 Years Of Asme Codes & Standards'. MEMagazine.

- ^Canonico, Domenic A. (February 2000). 'The Origins of ASME's Boiler and Pressure Vessel Code'. MEMagazine.

- ^ ab'The History of ASME's Boiler and Pressure Vessel Code'. ASME. March 2011. Retrieved 24 July 2015.

- ^'Standards and Certification Chronology'. History of ASME Standards. ASME. Retrieved 10 November 2011.

- ^ abcdefgAn International Code - 2010 ASME Boiler & Pressure Vessel Code Section VIII Rules for Construction of Pressure Vessels - Division 1. ASME. July 1, 2011.

- ^'BPV Complete Code - 2019'. ASME Boiler and Pressure Vessel Code - 2019 Edition. ASME. Retrieved July 8, 2019.

- ^'Codes & Standards Interpretations On-Line'. Codes and Standards Electronic Tools. ASME International. Retrieved 10 November 2011.

- ^'Code Cases of the ASME Boiler and Pressure Vessel Code'. ASME. Archived from the original on 18 July 2012. Retrieved 7 November 2011.

- ^ abcdefg'II. Materials'. Boiler and Pressure Vessel Code - 2010 Edition. ASME. Archived from the original on 10 October 2011. Retrieved 9 November 2011.

- ^§

- ^ ab'V. Nondestructive Examinations'. Boiler and Pressure Vessel Code - 2010 Edition. ASME. Retrieved 9 November 2011.

- ^§§§§

- ^ abcde'VIII. Pressure Vessels - Division 1'. Boiler and Pressure Vessel Code - 2010 Edition. ASME. Retrieved 9 November 2011.

- ^ abAn International Code - 2010 ASME Boiler & Pressure Vessel Code Section VIII Rules for Construction of Pressure Vessels - Division 2: Alternative Rules. ASME. July 1, 2011.

- ^ abAn International Code - 2010 ASME Boiler & Pressure Vessel Code Section VIII Rules for Construction of Pressure Vessels - Division 3: Alternative Rules for Construction of High Pressure Vessels. ASME. July 1, 2011.

Pressure vessel steel plate covers carbon steel and alloy steel grades, which are designed for use in making pressure vessels, boilers, heat exchangers and any other vessels and tanks that to store liquid or gas at high pressures. It includes applications like below or similar:

- Crude Oil Storage Tanks

- Natural Gas Storage Tanks

- Chemicals and Liquid Storage Tanks

- Firewater Tanks

- Diesel Storage Tanks

- Gas Cylinders for Welding

- Gas Cylinders for Cooking in peoples daily life

- Oxygen Cylinders for Diving

There are a wide range of different liquid and chemicals that need to be stored under pressure. Such us food, milk, plam oil, crude oil, natural gas includes their distillates to highly lethal acides which is bad to environments, so these liquid or gas shall be kept in high or low temperatures. Therefore, pressure vessel plates covers a wide range of steel grades which to use in different cases.

Pressure Vessel Plate Commonly Ranged in There groups of Steel Material

Steel plates material used for pressure vessels commonly could be divided into three groups.

Carbon Steel Pressure Vessel Grades

Carbon steel pressure vessel steel plates are general use vessel plates that includes several standards and grades.

ASTM A516 Gr 70/65/60 Steel Plate

Used inModerate & Low Temperature

ASTM A537 CL1, CL2 Steel Plate

Heat-treated With Higher Strength than A516

ASTM A515 Gr 65, 70

Pressure Vessel Nameplate Data Chart

For Intermediate & Higher Temperature

ASTM A283 Grade C

Low & Intermediate Strength Steel Plate

ASTM A285 Grade C

For Fusion Welded Pressure Vessels in as rolled Condition

Pressure Vessel Steel provides premium quality carbon steel plate for boiler and pressure vessel fabrication which is perfectly suited to the high standards set by the oil, gas, and petrochemical equipment, Octal stocks a wide range of dimensions of ASTM A516 GR70, A283 Grade C, ASTM A537 CL1/CL2.

Low Alloy Pressure Vessel Grades

With adding alloy elements like chromium, molybdenum, or nickel will increase steel heat and corrosion resistances. These plates also known as Chrome Moly Steel Plates.

ASTM A387 Crade11, 22 Steel Plate

Chromium-Molybedenum Alloy Steel Plate

Pressure Vessel Nameplate Requirements

The material grades that between pure carbon steel pressure vessel grades and stainless steel plates. Typically standards is ASTM A387, 16Mo3 these steels have improved corrosion and temperature resistance over the standard carbon steels but without the cost of stainless steels (due to their lower nickel and chromium content).

Stainless Steel Vessel Grades

By adding the certain percent of chromium, nickel and molybdenum, will increase highly resistant of stainless steel plates, for to use in critical applications that require highly resistant to the environment. Such as used in food or chemical industries.

The manufacture of pressure vessels is tightly regulated as a result of the risks involved and as a consequence the materials that can be used in vessels is also tightly specified. The most common specifications for pressure vessel steels are the EN10028 standards – which are European in origin – and the the ASME/ASTM standards which are from the US.

Pressure Vessel Nameplate Data Types

We can also supply high specification pressure vessel steel plate used in the oil and gas industry and specifically in steel plate resistant to Hydrogen Induced Cracking (HIC).

HIC Resistant Pressure Vessel Steel Plate (NACE)

Pressure Vessel Nameplate Stampings

These plates served in equipment used in H2S-containing environments (for sour services), H2S is a harmful chemicals that mostly easy to generate the corrosion especially in oil and gas production. Refered standard is NACE MR0175.